ER3003 aluminum MIG welding wire

Author: Time:2023-05-17

ER3003 is the aluminum manganese alloy for welding, aluminum alloy electwiree for base type coating.

Its characteristic is that the cold wind strength is higher, the corrosion resistance and the pure aluminum

are almost the same. DC power supply, welding electwiree, short arc welding. Arc stability is poor, the

splash is relatively large.

are almost the same. DC power supply, welding electwiree, short arc welding. Arc stability is poor, the

splash is relatively large.

Uses: used in the welding of aluminum manganese alloy, pure aluminum and other aluminum alloys.

Note:

| Mechanical Properties (reference value) | ||

|---|---|---|

| Item | Tension Strength(MPa) | Cold bending angle D=2T |

| Standard | ≥95 | - |

| Result | 120--135 | 120--180 |

| Reference current: DC+ | |||

|---|---|---|---|

| Welding wire Diameter(mm) | 3.2 | 4.0 | 5.0 |

| Welding Current(A) | 80--110 | 110--150 | 150--200 |

| ER3003 Aluminium & Aluminium Alloy welding wires | |

| Classification | GB/T 10858-2008 AWS A5.10 ···· ER 3003 |

|

Typical composition in % |

Si················ <0.60 Fe················ <0.70 Cu················· 0.05—0.20 Mn················· <1.0--1.6 Zn·················· <0.10 Al·················· Remaining |

| Shielding gas | Argon, Helium, or Argon/Helium—mixtures. |

| Dimensions Φ |

MIG—wires (mm): 0.8 ; 0.9 ; 1.0 ; 1.2 ; 1.6 ; 2.0 ; 2.4 TIG —wires(mm): 1.6 ; 2.0 ; 2.4 ; 3.2 ; 4.0 ; 5.0 ; 6.0 |

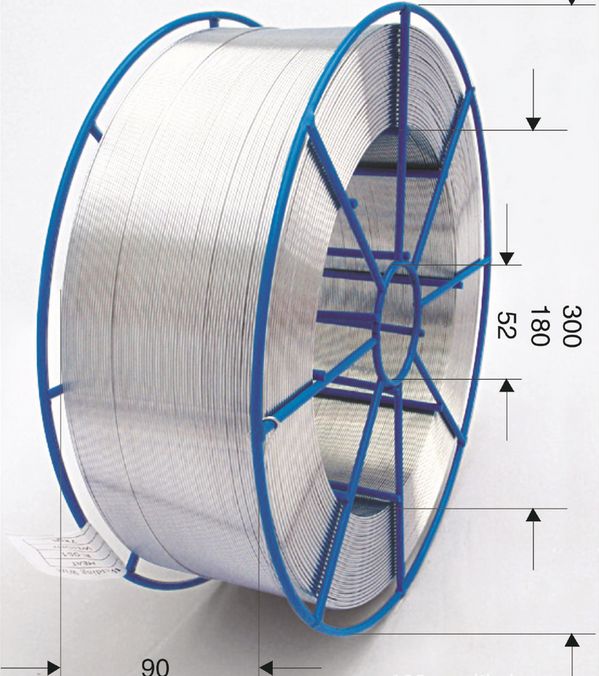

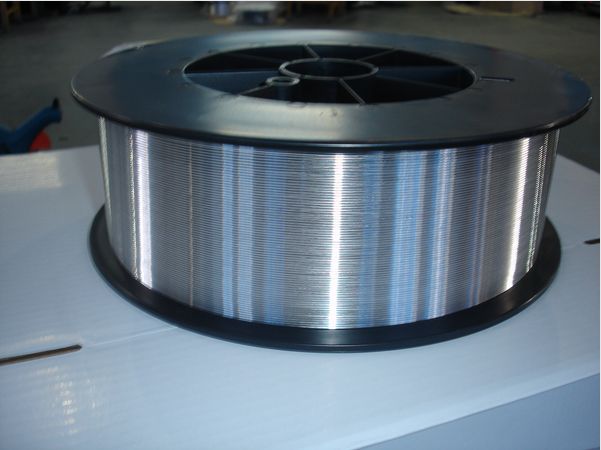

| wire Packagings |

Mig wires : S100/0.5kg 1Lb , S200/2kg , S270-S300/6kg-7kg |

|

Tig wire ) : 5/10kg ······· length :1000mm |

|

Note:

1. Electwiree is extremely easy to be affected with damp, so should be stored in dry sealed containers, in order

to prevent damp metamorphism.

to prevent damp metamorphism.

2. Before welding, the welding wire is about 150 degrees Celsius for 1-2 hours.

3. Should be welded by plate, and to 200--300 degrees after welding according to the thickness of heating

welding. Welding process, the welding wire does not do the lateral swing, in order to improve the welding

speed, welding electwiree should be perpendicular to the surface, the arc should be as short as possible.

Replacement of electwiree must be carried out quickly.

welding. Welding process, the welding wire does not do the lateral swing, in order to improve the welding

speed, welding electwiree should be perpendicular to the surface, the arc should be as short as possible.

Replacement of electwiree must be carried out quickly.

4. The welding parts must be clear before welding, impurities. After welding should carefully clear slag, and

use steam or hot water washed clean.

use steam or hot water washed clean.