ER4043 aluminum MIG welding wire

Author: Time:2023-05-17

ER4043 is a silicon containing 5% of aluminum silicon alloy welding wire, good fluidity, heat cracking ability, but the lack of ductility. Because of the high silicon content, it is easy to pwireuce the brittle Mg2Si in the weld, so that the plastic and corrosion resistance of the joints can decrease. In addition, the color of the surface of the weld is dark, and the color of the base material is different from that of the base metal.

Use: used as filling materials except aluminum magnesium alloy, aluminum alloy parts and castings and the gas welding argon arc welding. Welding used in the 6061 and 6000 series aluminum alloy, 3000 series and 2000 series aluminum alloy and cast aluminum. Widely used in railway locomotives, chemical, food and other industries.

| Physical Property | ||||

|---|---|---|---|---|

|

Density kg/dm3 |

Melting temperature ℃ |

Thermal conductivity w/m•K |

Linear expansion coefficient 10¯6/K(20-100℃) |

Electric conductivity % IACS |

| 2.67 | 573-625 | 163 | 22 | 42 |

| Weld Mechanical Properties (reference value) | ||

|---|---|---|

| Tension Strength(MPa) | Yield Strength(MPa) | Elongation (%) |

| 120--150 | 50--65 | 10--18 |

| ER4043 Aluminium & Aluminium Alloy welding wires | |

| Classification |

GB/T 10858-2008············ HS 311 AWS A5.10·············· ER 4043 |

|

Typical composition in % |

Si·················· 4.50—5.50 Fe·················· <0.80 Cu··················· <0.30 Mn··················· <0.05 Mg··················· <0.05 Zn··················· <0.10 Be················· <0.0003 Ti················· <0.20 Others··············· <0.05 Others Total·········· <0.15 |

|

Physical properties (Approx.Values) |

0.2% yield strength Rpo2 (Mpa)···· 40 Tensile Strength Rm (Mpa)····· 120 Elongation A5 (L0=5d0) (%)······ 8 Test Temperature (℃)····· 20 |

|

Performance & Usage |

This type containing 5% silicon,which can be adapted in welding all kinds of forging and casting alloys.With the good performance in anti-thermal crack. Usage:ships,engine,mold,furniture,vessel,container,etc. |

| Shielding gas | Argon, Helium, or Argon/Helium—mixtures. |

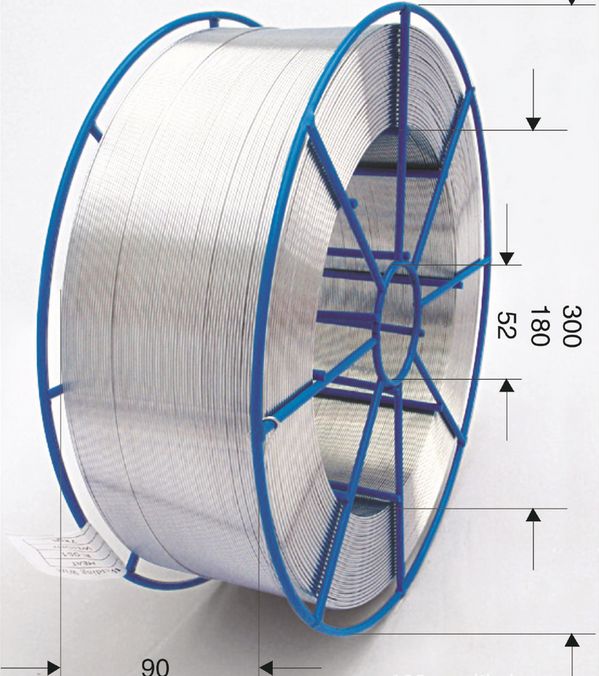

| Dimensions Φ |

MIG—wires (mm): 0.8 ; 0.9 ; 1.0 ; 1.2 ; 1.6 ; 2.0 ; 2.4 TIG —wires(mm): 1.6 ; 2.0 ; 2.4 ; 3.2 ; 4.0 ; 5.0 ; 6.0 |

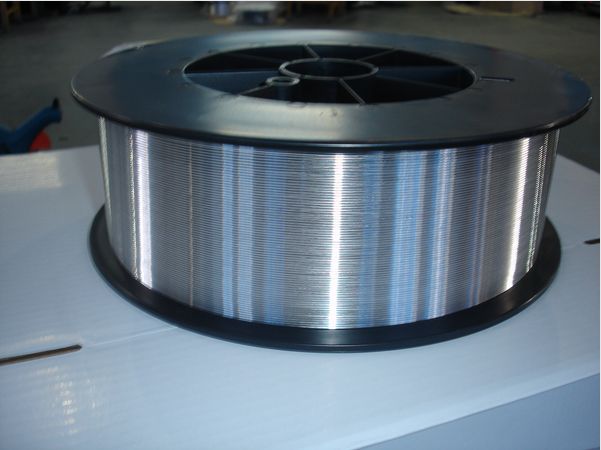

| wire Packagings |

Mig wires: S100/0.5kg 1Lb , S200/2kg , S270-S300/6kg-7kg |

|

Tig wire : 5/10kg ······· length :1000mm |

|

Note:

1. Al Si wire while having a strong crack resistance, but plastic is poor, so after welding need plastic

deformation joints, should avoid using aluminum silicon wire.

deformation joints, should avoid using aluminum silicon wire.

2 . The oxide and oil stain on the edge of the workpiece must be removed before welding.

3. Welding can be used to hold the molten metal plate, in order to ensure