ER4047 aluminum MIG welding wire

Author: Time:2023-05-17

ER4047 is a eutectic Al Si alloy with 12% silicon, low melting point, good fluidity, and has good corrosion

resistance. But it is anodized after the color is black.

Application:

suitable for Al Si, Al Si mg, Al Si Cu mg wrought aluminum and aluminum (>7%Si) argon arc

welding. More widely used for pure aluminum, aluminum manganese, aluminum silicon magnesium alloy.

suitable for Al Si, Al Si mg, Al Si Cu mg wrought aluminum and aluminum (>7%Si) argon arc

welding. More widely used for pure aluminum, aluminum manganese, aluminum silicon magnesium alloy.

| Density kg/dm3 | Melting temperature ℃ | Electric conductivity % IACS |

|---|---|---|

| 2.65 | 573---585 | 41 |

| Weld Mechanical Properties (reference value) | ||

|---|---|---|

| Tension Strength(MPa) | Yield Strength(MPa) | M |

| 160--190 | 70--85 | 10--15 |

| ER4047 Aluminium & Aluminium Alloy welding wires | |

| Classification | GB/T 10858-2008 AWS A5.10··· ER 4047 |

|

Typical composition in % |

Si················ 11.00—13.00 Fe················ <0.60 Cu················ <0.30 Mn················ <0.15 Mg················ <0.10 Zn················ <0.20 Be················ <0.0003 Ti················ <0.15 Others············· <0.05 Others Total········· <0.15 |

|

Physical properties (Approx.Values) |

0.2% yield strength Rpo2 (Mpa)····· 60 Tensile Strength Rm (Mpa)····· 130 Elongation A5 (L0=5d0) (%)······ 5 Test Temperature (℃)······ 20 |

|

Performance & Usage |

This type containing 12% silicon,which can be adapted in welding all kinds of forging and casting or extruded shape aluminium alloys.And it has advantages of low melting point and good fluidity which avoids the distortion after welding. Usage:jointing or overlay light alloy processing. |

| Shielding gas | Argon, Helium, or Argon/Helium—mixtures. |

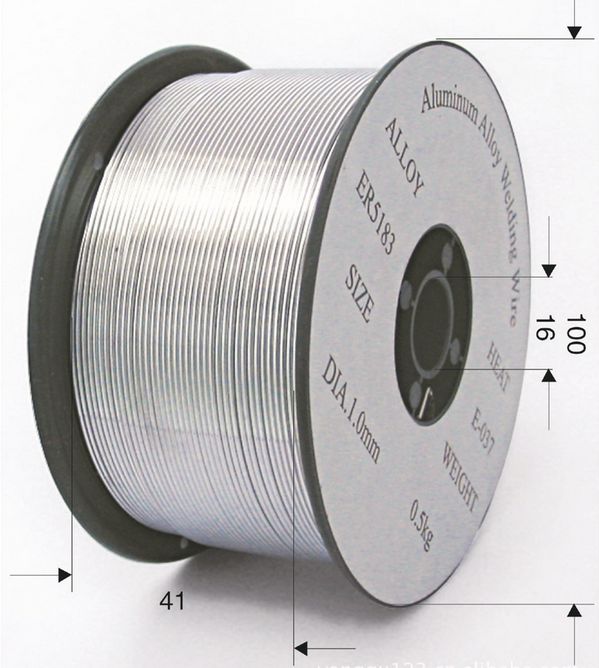

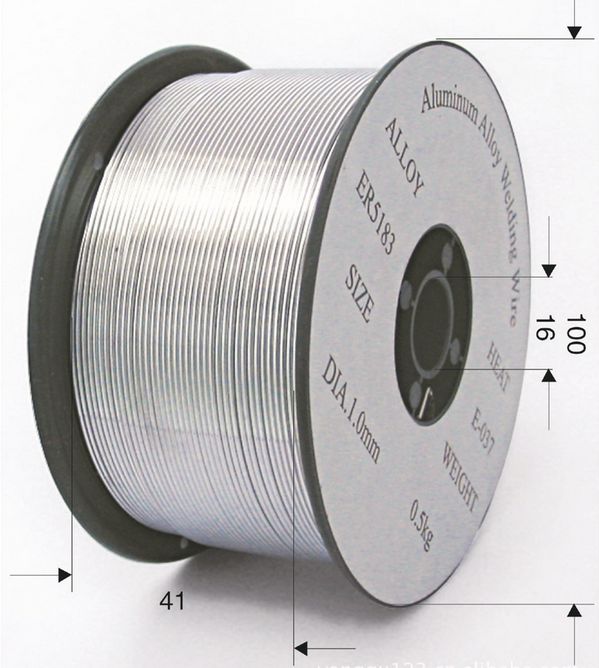

| Dimensions Φ |

MIG—wires (mm): 0.8 ; 0.9 ; 1.0 ; 1.2 ; 1.6 ; 2.0 ; 2.4 TIG —wires(mm): 1.6 ; 2.0 ; 2.4 ; 3.2 ; 4.0 ; 5.0 ; 6.0 |

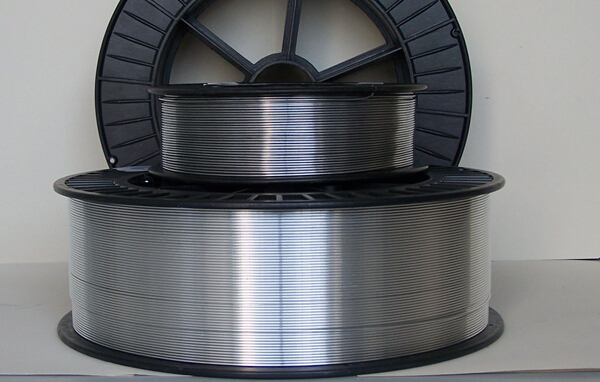

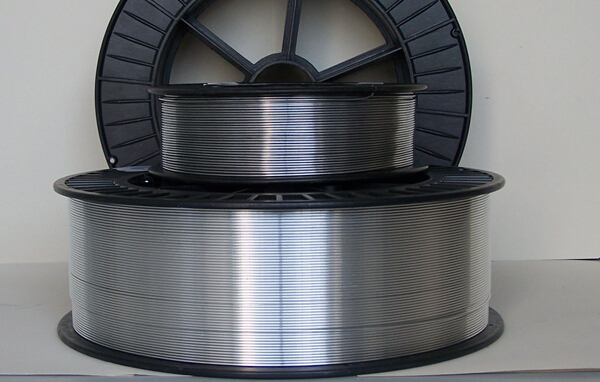

| wire Packagings |

Mig wires: S100/0.5kg 1Lb , S200/2kg , S270-S300/6kg-7kg |

|

Tig wire : 5/10kg ······· length :1000mm |

|

Note :

1. Al Si wire although there are strong crack resistance, but plastic is poor, so after welding need plastic

deformation joints, should avoid using aluminum silicon wire.

deformation joints, should avoid using aluminum silicon wire.

2. The oxide and oil stain on the edge of the workpiece must be removed before welding.

3. Welding can be used when the plate holding molten metal, to ensure weld forming.